How 3D Printing is Disrupting Manufacturing and Design

3D printing technology is rapidly transforming the manufacturing and design industries by offering unprecedented capabilities in rapid prototyping, customized production, and sustainable practices. This revolutionary technology is reshaping how products are conceived, created, and delivered.

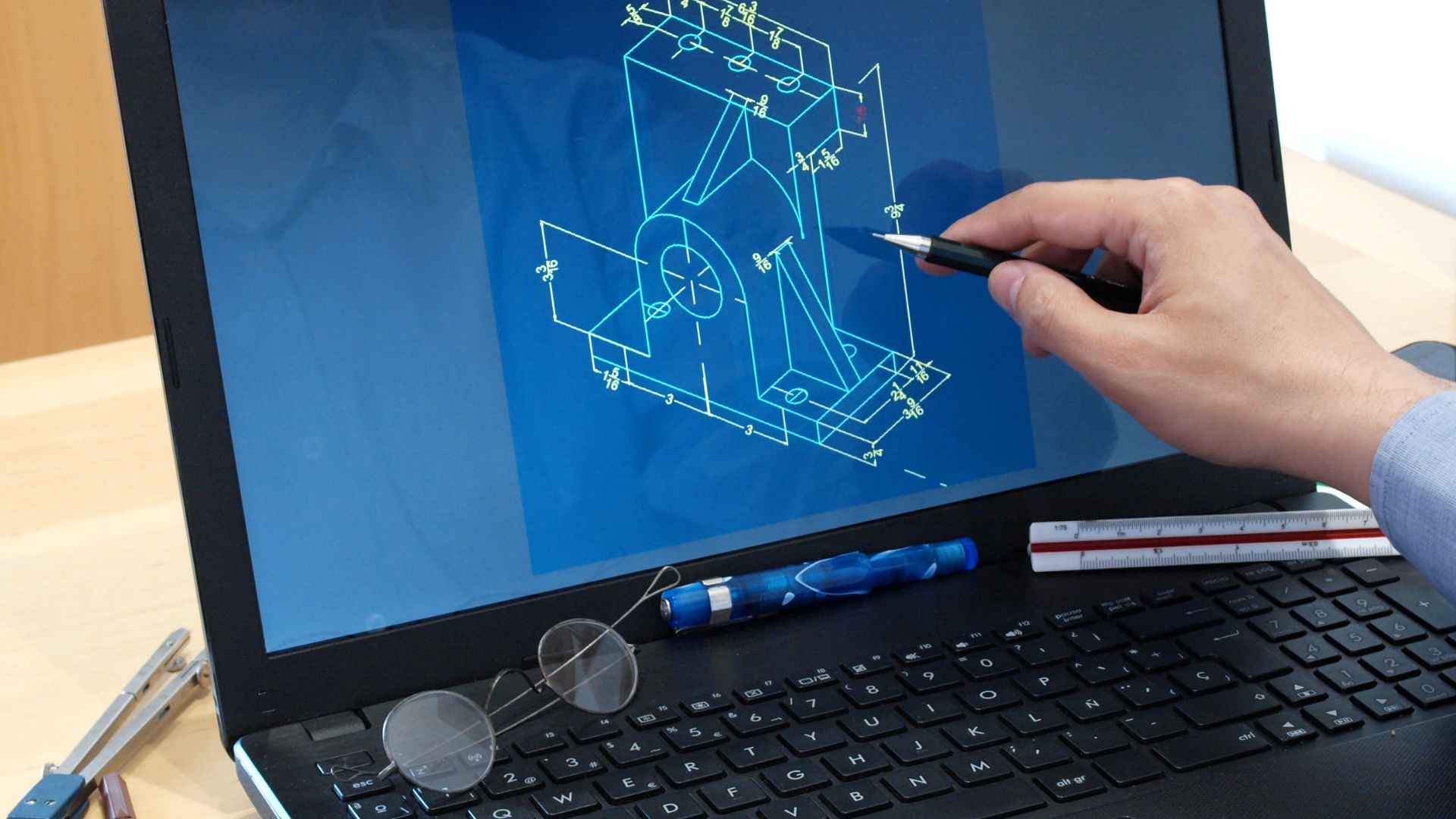

- Rapid Prototyping: One of the most significant impacts of 3D printing is its role in rapid prototyping. Traditionally, developing prototypes involved lengthy and costly processes. 3D printing, however, allows designers and engineers to quickly create and test prototypes, drastically reducing development time and costs. This iterative approach accelerates innovation and enables more efficient product development cycles.

- Customized Production: 3D printing excels in producing customized and complex designs that are difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in industries like healthcare, where bespoke medical implants and prosthetics can be tailored to individual patients. Similarly, in consumer goods, companies are able to offer personalized products, from custom-fit eyewear to bespoke jewelry, enhancing customer satisfaction and engagement.

- Sustainable Manufacturing: The environmental impact of traditional manufacturing processes is a growing concern, but 3D printing presents a more sustainable alternative. This technology minimizes waste by using only the material needed for the final product, reducing excess material and energy consumption. Additionally, 3D printing can facilitate on-demand production, reducing the need for large inventories and associated waste.

- Innovations in Design: 3D printing has also expanded the possibilities in design, allowing for the creation of intricate geometries and structures that were previously unattainable. This innovation opens up new avenues for creativity in architecture, aerospace, and automotive industries, where complex, lightweight components can enhance performance and efficiency.

- Future Potential: As 3D printing technology continues to advance, its potential applications are expanding. Emerging developments in materials science and printing techniques promise even greater versatility and capabilities. Industries are exploring possibilities such as 3D-printed buildings and advanced aerospace components, showcasing the transformative power of this technology.

In summary, 3D printing is disrupting manufacturing and design by enabling rapid prototyping, customized production, and sustainable practices. Its ability to transform how products are developed and produced is driving innovation and efficiency across various industries, making it a cornerstone of modern manufacturing and design.